We aim to harness our cultivated strengths to perform as a one and only best-in-class company.

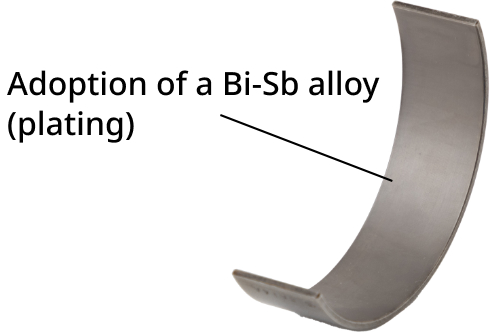

We continue to take on new challenges by leveraging the core technologies we have cultivated, guided by our keywords: 'Deepening' and 'Exploration.' With plain bearings as our main business, we have advanced research and development of bearing materials based on tribology technology.

Through our integrated in-house system, which covers everything from material development to production, we have been able to provide our clients with bearings that deliver outstanding performance. In the field of "exploration" that we are pursuing, we are further expanding our knowledge in material development to adapt to changes in the times, and we are striving for unique, unparalleled performance in new areas as well.

| Deepening (bearing materials) |

|

|---|

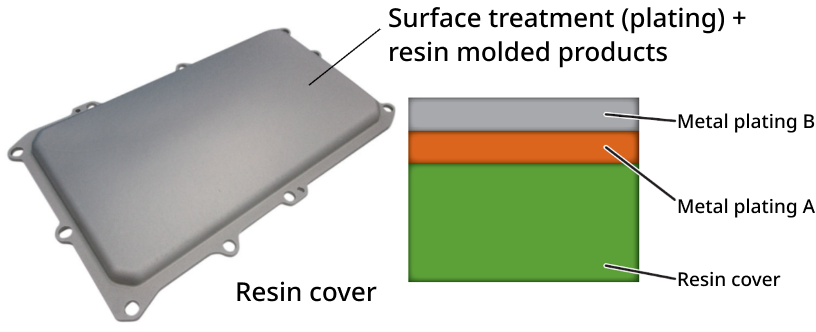

| Exploration (electrified materials) |

|

|---|

We provide innovative solutions to the challenges of thermal management in electric vehicles through material technology.

With "carbon neutrality" as the key driver, the automotive industry is rapidly transitioning from engine-powered vehicles to electric vehicles. To respond to this wave of electrification, we are exploring new materials and developing products with unique, one-of-a-kind technology.

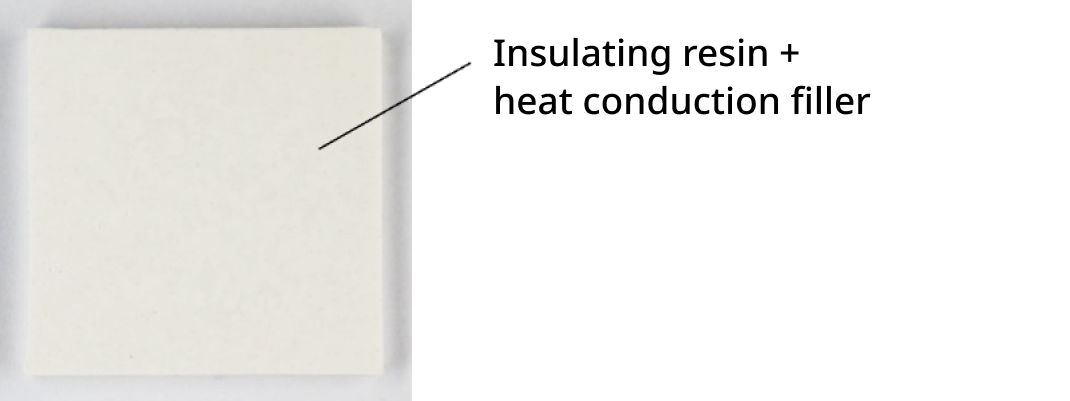

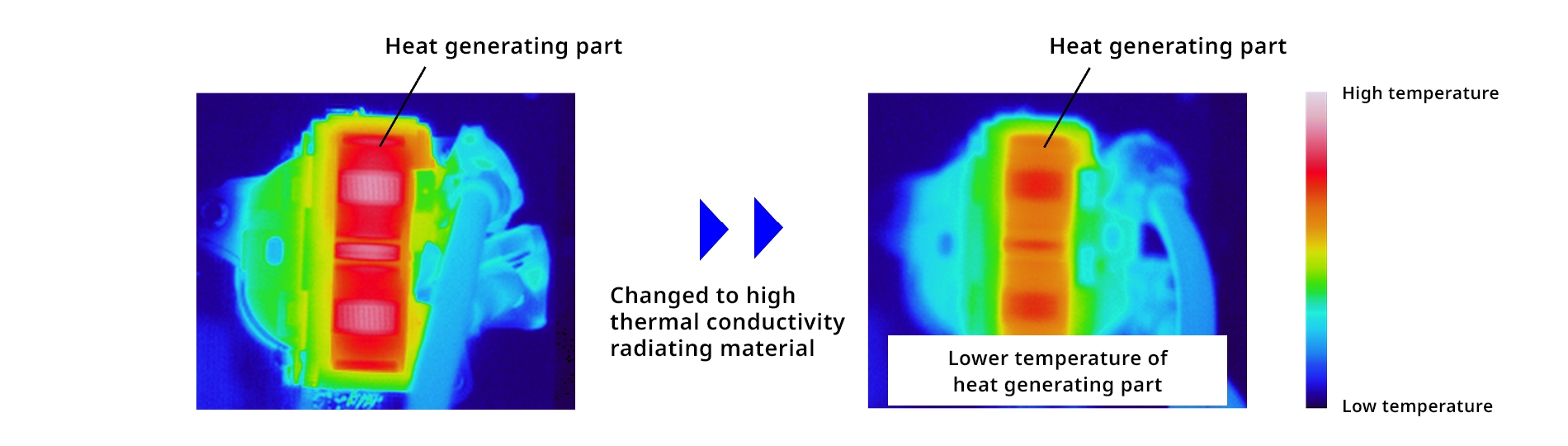

Thermal management in electric vehicles is a significant challenge. At high temperatures, there is a risk of reduced power generation efficiency and component degradation. To address this, we are leveraging our expertise in material development to create new heat dissipation materials.

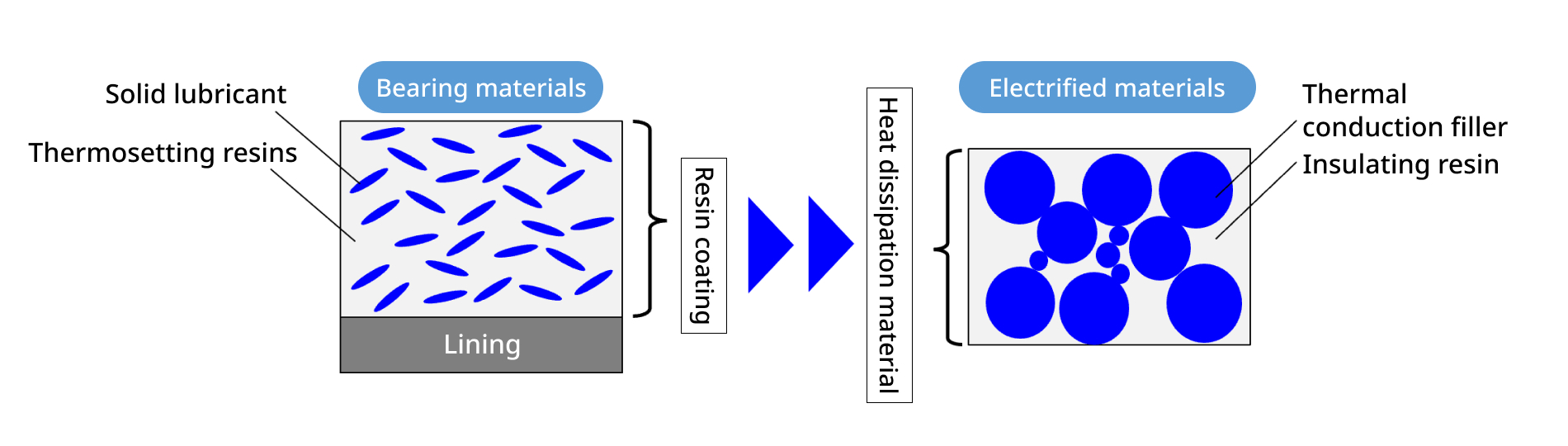

For example, in the resin coating of bearings, it is crucial to uniformly disperse solid lubricants to enhance tribological properties. We have advanced material design, solid lubricant dispersion, analysis, and evaluation technologies to achieve this uniform dispersion. Improving the thermal conductivity of heat dissipation materials requires precise control over the dispersion of thermally conductive fillers.

We believe that the filler dispersion techniques we have developed in bearing materials can also be applied to heat dissipation materials. By combining our existing technologies with new advancements and taking a comprehensive approach from prototyping to basic evaluation, real-world testing, and material analysis, we are committed to developing innovative heat dissipation materials.

We continuously pursue expertise, combining our technologies with cutting-edge advancements to realize next-generation innovations.

Our experience in developing bearing materials, from metals to resins, serves as an essential foundation for our material development efforts. With a focus on specialization, we actively incorporate cutting-edge technology through industry-academia collaboration, continuously striving for innovation.

By keeping up with the constantly evolving trends in the automotive industry and promoting material development with an eye on future needs, we are committed to remaining an indispensable partner for our customers.