We aspire to be the one and only company to engage in new product development that keeps us as a reliable partner.

Since we were founded, we have been focused on being the one and only manufacturer that can be trusted in terms of quality, performance, and service. By keeping alive the spirit that we have managed to maintain with our existing stable of products, we now face a challenge posed by a period of change of the sort that is likely to occur once every century in the automotive industry.

As we seek to innovate with tribology as the essence of our core technology, we note that our watchwords are deepen and exploration. By taking on new challenges and both undergoing change and being the agent of change ourselves, we hope to turn these changes into opportunities for more dramatic leaps forward.

Our organizational structure is also changing to enable core technologies to be harnessed for new product development.

We significantly changed our organizational structure as well to allow us to take on the challenge of developing new products. We formed a new product development team consisting of advanced development members to promote the development of products to accommodate electrification. This development team works on design functions, the development of materials, computational analysis (MBD), and the development of manufacturing methods and also brings in advanced development members of Group company Nippon Gasket to quickly achieve development results from multiple angles.

Accelerating initiatives through a “deepening and explorative organization”

In order to accelerate deepening and explorative initiatives, we shifted from being a product-oriented organization that used to be grouped by product (such as bearings and system products) to being a deepening and explorative organization that is divided into existing areas (to be deepened) and new areas (to be explored) and are pursuing specific initiatives accordingly.

Deepening in terms of analyses and evaluations

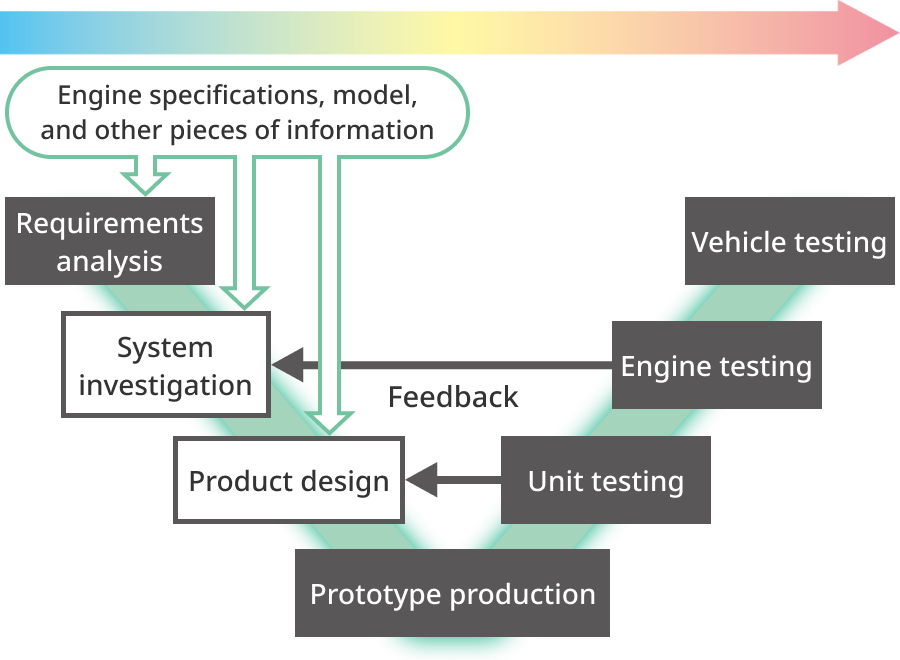

Computational analysis (MBD) is a highly specialized field. We perform tribological analysis on a contracted basis. We are also working on development projects in the area of thermal management with the aim of becoming a partner for our clients. We also possess advanced technology for evaluating performance and reliability and perform engine evaluations and other such services on a contracted basis.

Deepening MBD technology for realizing system proposals

Analysis techniques

Latest Case Study)NV Prediction Around the Crankshaft

Presented a lecture at the 2021 Society of Automotive Engineers of Japan Chubu Branch Research Conference.

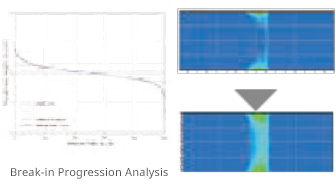

Latest Case Study)EHL Analysis Considering Break-in and Wear Progression.

Presented at the 2022 Society of Automotive Engineers of Japan Spring Conference.

Development process

In 2023, we were among the first to introduce equipment to evaluate the generation of fuel cell (FC) power.

A framework is in place to enable the entire company to work together. Indeed, our strength lies in the fact that our young employees definitely pull their own weight.

We believe that the ideas and imagination of each young individual in our company are vital in getting these individuals to begin developing products without inhibition. In order to have our technologies harnessed for not just automobiles but also various everyday products, we will build a spirit and organization of development capable of constantly piquing the curiosity of our employees.