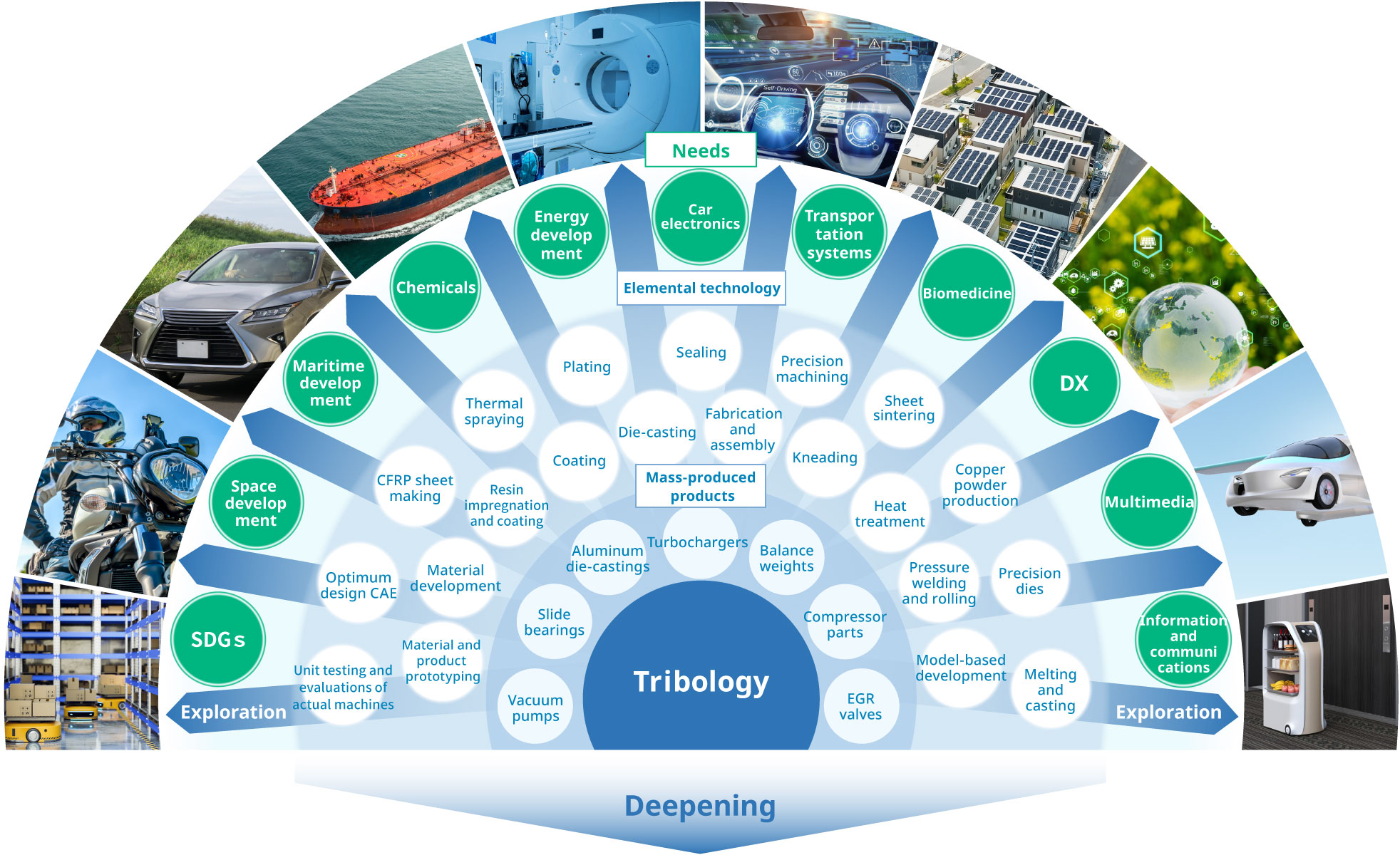

Products and technologies developed from tribology

Technologies cultivated with automotive parts are being deployed across various other industrial fields.

Tribology is drawing attention as a technological concept through which friction is controlled. Its study is indispensable in the pursuit of energy conservation and comfort across fields ranging from industrial machinery to services. In aiming to reduce friction in automobiles through the application of tribology, we are developing material and design technologies and have established an integrated production system to achieve an optimized approach to manufacturing.

With these technologies treated as core technologies, we will define a global standard for technologies that transcend barriers not just with respect to automobiles but also in such fields that are closely intertwined with the lives of people as space, information, and medicine and pursue product development in a manner that is captivating.

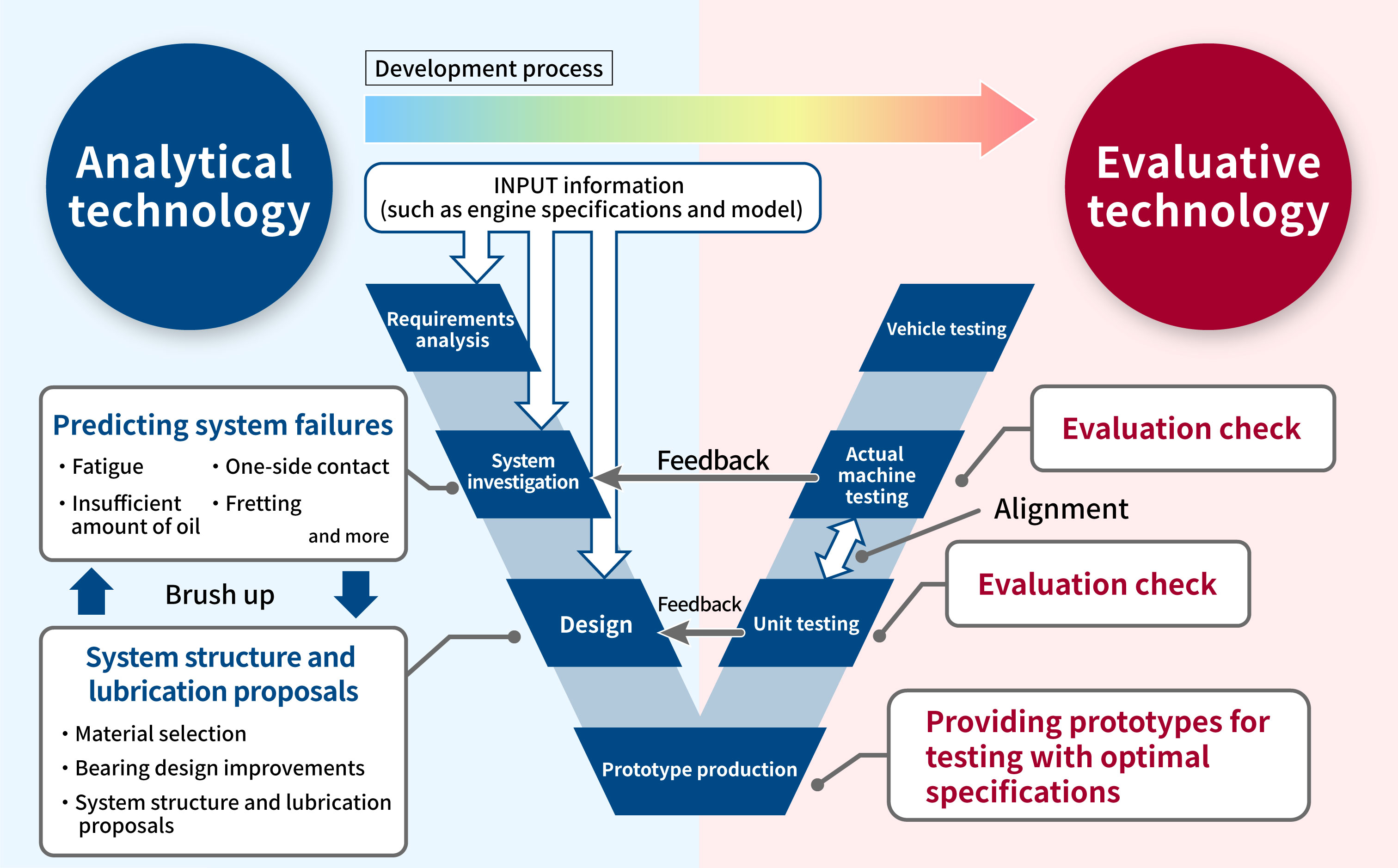

We propose optimal specifications by completing design investigations in the upstream section of the V process.

Analyses and simulations, which are upstream processes in the V process, and unit testing and evaluations of actual machines, which are downstream processes, are all performed in-house. Directing feedback of evaluation results into the analytical technology makes it possible to improve the strength and precision of model-based development (MBD). Accordingly, optimal high-precision specifications can be proposed from the outset of development, which can help speed up development work for clients and reduce man-hour requirements.