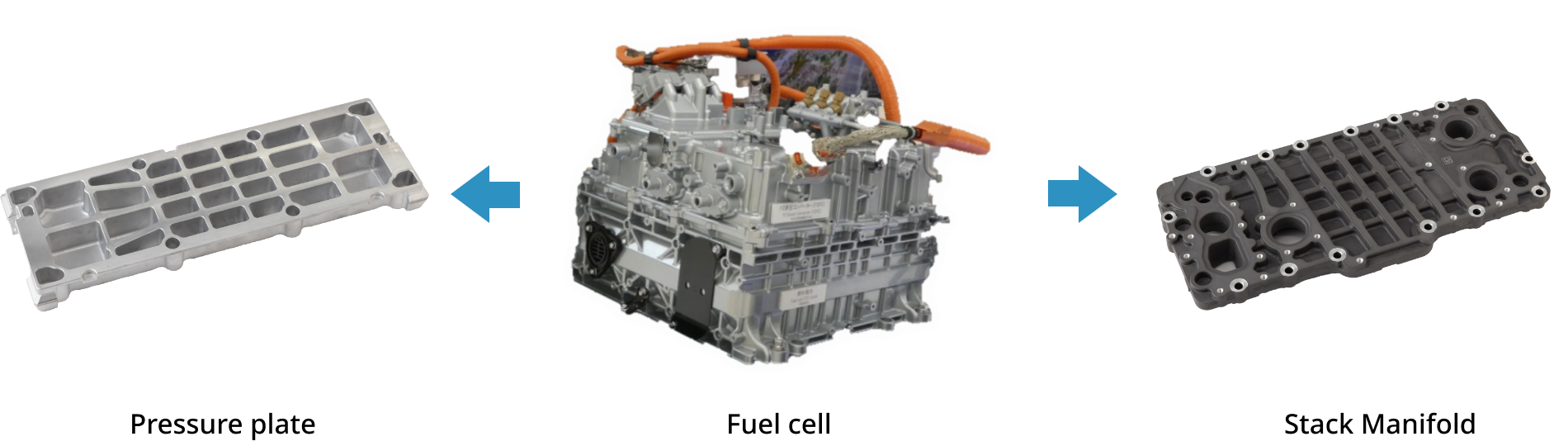

Development aims

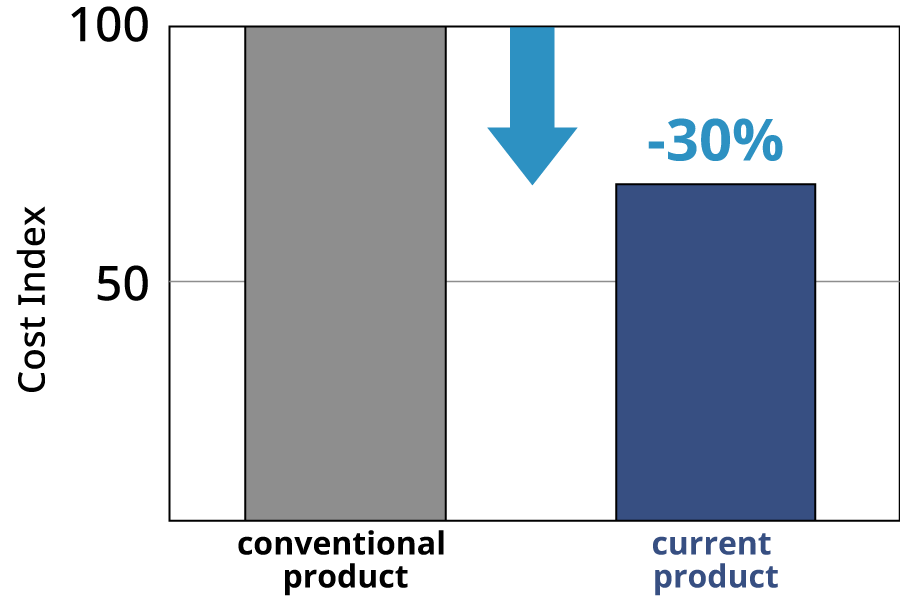

To lower costs

- Downsizing of casting machines: 1,250t → 800t

- Weight reduction thanks to an optimal rib design

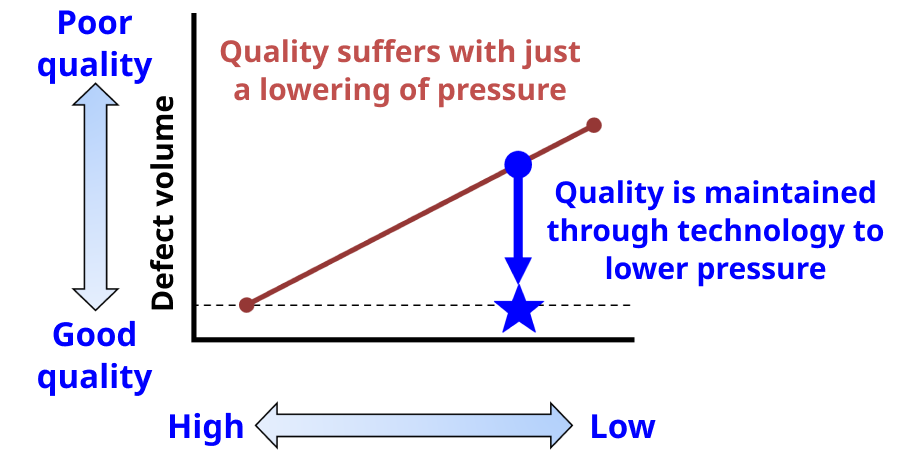

Downsizing of casting machines

Technology to reduce casting pressure

Die temperature control

Practical application of die surface treatment

CAE-based predictions of casting defects (product form and casting plan)

Increased sleeve filling rate

casting cost by approximately 30%

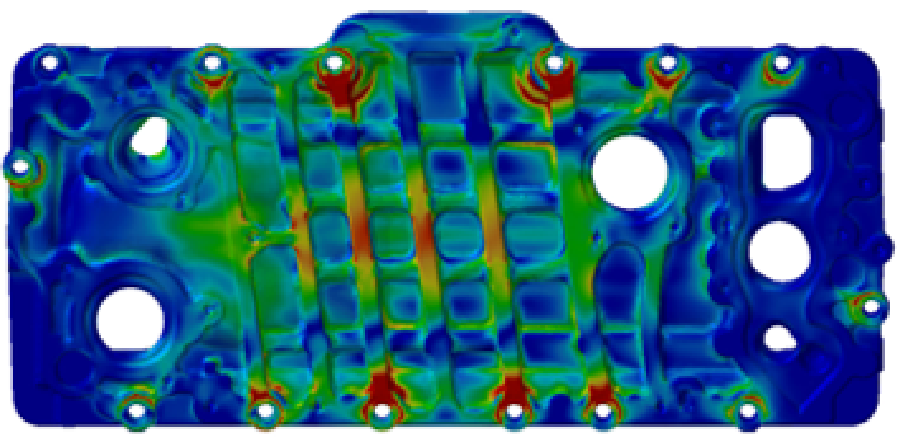

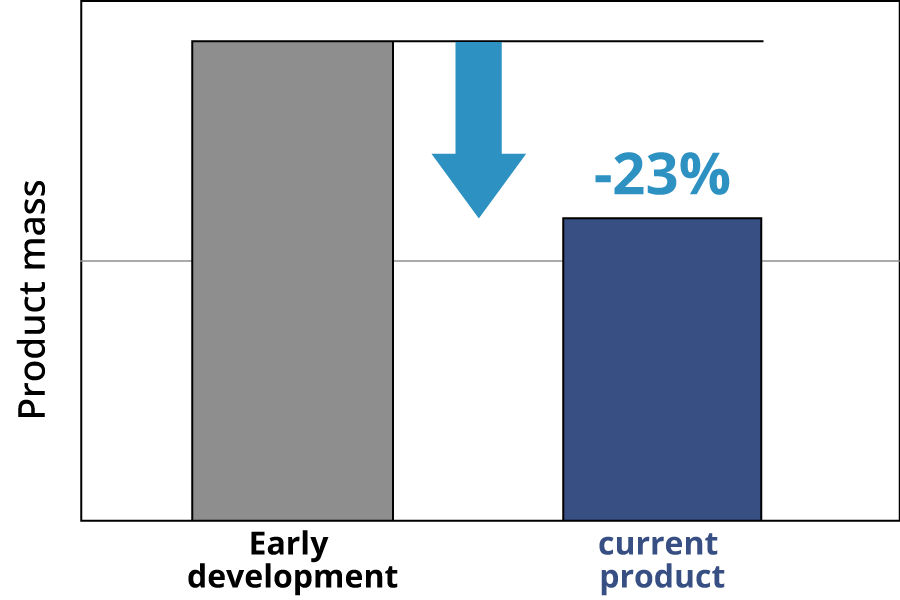

Weight reduction thanks to an optimal rib design

Calculating strength with the use of CAE

Optimal rib placement has been designed with a focus on both the necessary strength and the manufacturing requirements

the weight was reduced by 23%.