In-house rubber composition → Customizable according to the required characteristics

Combining compression set, gas barrier properties, resistance, and low temperature resistance

| Item | measured value | |

|---|---|---|

| Compression set | 18% @90℃×1000h(compressive permanent strain) | |

| Hydrogen barrier properties | 5.0×10-14 mol・m/(m2・s・Pa) | |

| Water permeability | 7.2g/(m2・2.4h) @80℃ | |

| Resistance | 5×1014 Ω・cm | |

| Low temperature resistance TR65 | -30℃ | |

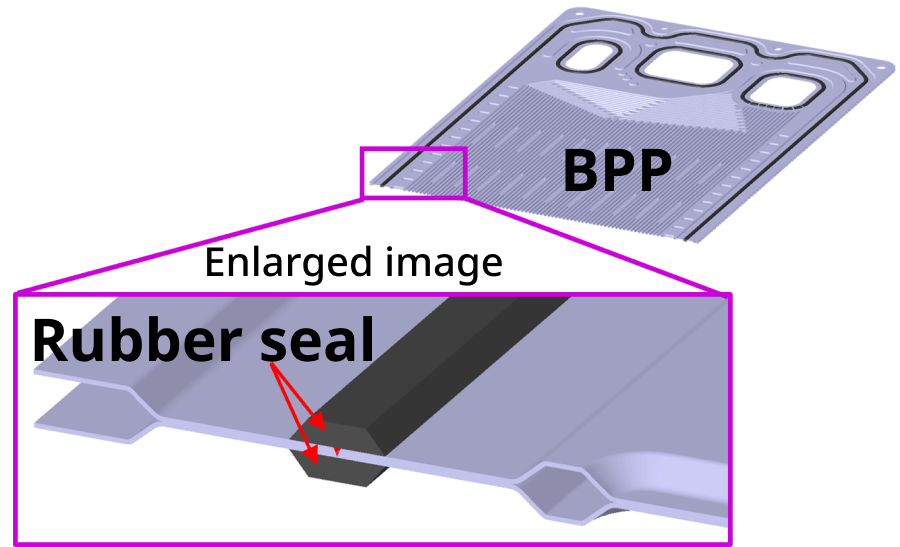

| Rubber seal | Sealability | 14belowPa(Pressure drop value for 5S at 350kPa) |

| Adhesive strength | 0.66N/mm | |

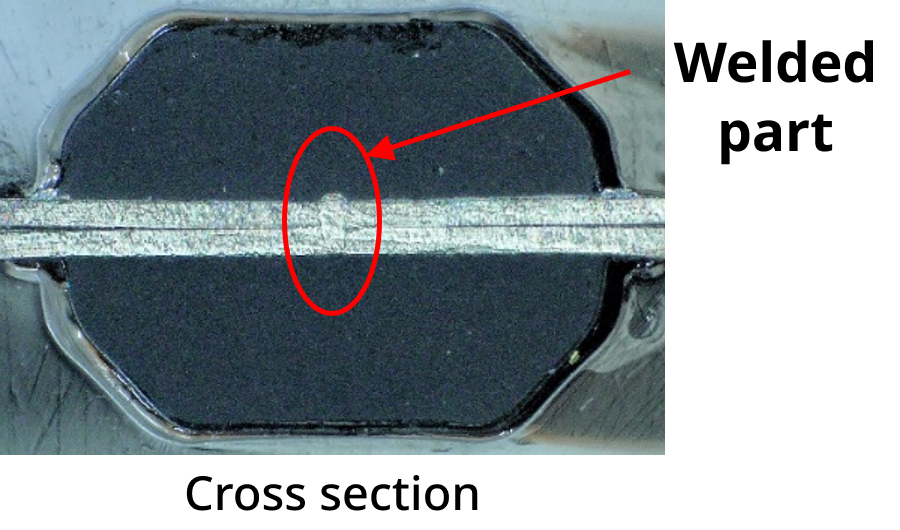

Low-cost rubber molding → Molding on the welded part, one-time mold on both side

One-time mold on both anode and cathode side

Rubber molding is possible even on the welded area. Therefore, possible to increase the power generation area.

Prototype rubber seals can be made to your specifications.