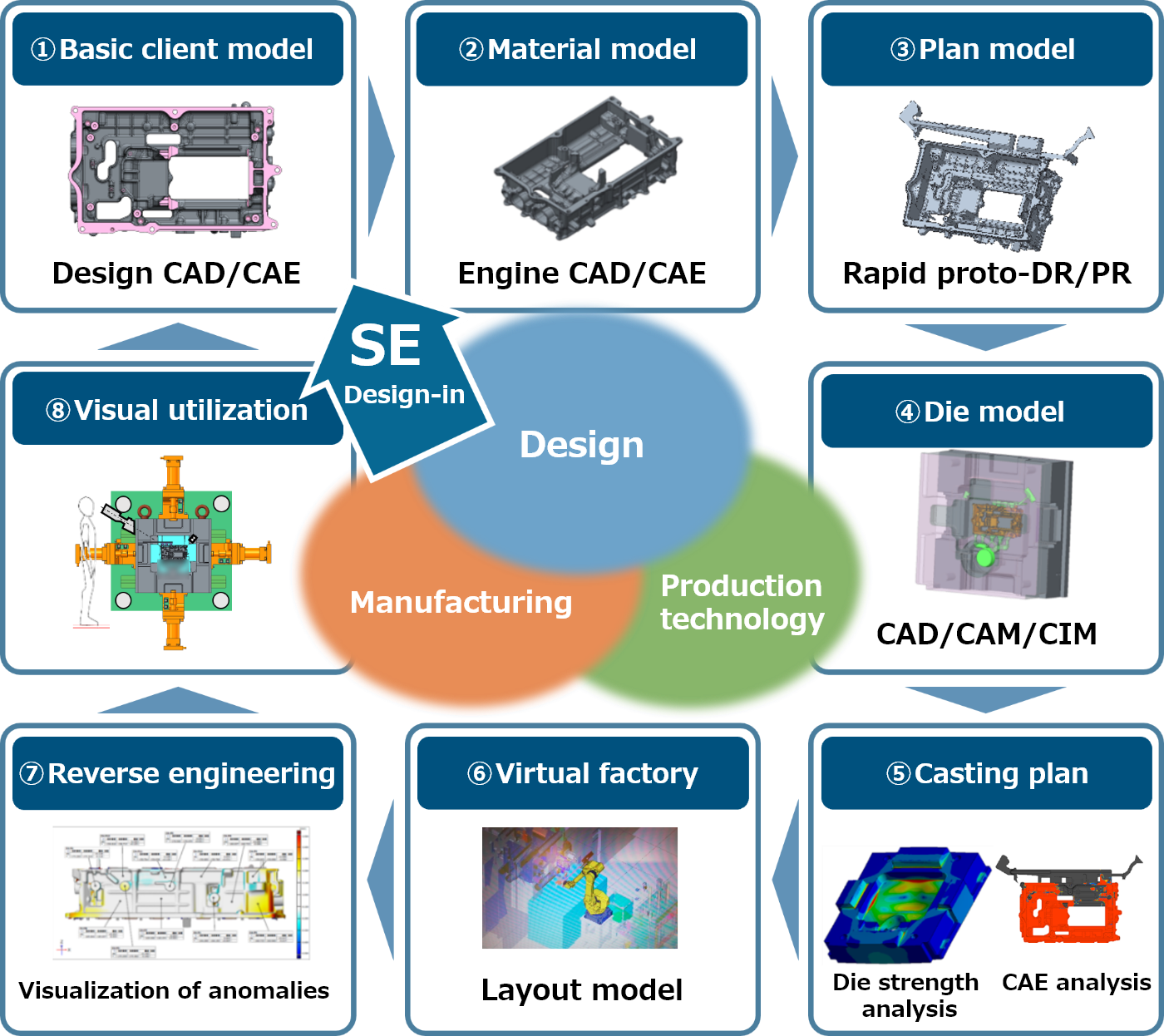

SE design proposals are put forth quickly through integrated development facilitated by the sharing of 3D models.

Conducting shape examinations (SE) with a focus on manufacturing for base models and CAE analyses with casting plan models and providing feedback to the design stage from the outset of development help to promote development for which there can be no retrogression and the provision of good, low-cost products. In addition, reverse engineering on actual products based on the use of 3D measurements allows for the detection of anomalies at an early stage and the making of proposals for improvement.