Material development

Material-development technology amassed over many years

The development of materials in line with client needs and applications

We engage in everything from the study of material components to prototyping and evaluations on an integrated basis based on data accumulated over many years. We have on hand various stand-alone testing machines and actual condition testing machines that can be made to correspond to various bearing applications. By combining electron microscopes needed to analyze testing results in detail and other types of analytical equipment and CAE technology to conduct evaluations of materials, we can provide highly reliable materials that meet the needs of our clients. We manage to develop materials quickly by developing demonstration lines that simulate assumed mass-production lines and configuring manufacturing conditions from the initial stages of the development process.

Alloy design

Alloy design based on thermodynamics and the use of data on bearing materials amassed over many years

Prototyping of materials

Small-lot prototyping on trial production lines is possible

Analysis

Analysis by SEM, EPMA, XRD, OM, LM, DTA, FTIR, and other techniques can be performed.

Unit testing

Basic tribology testing machines, bushing/washer testing machines, compressor bearing testing machines, and other testing machines

Actual machine evaluations

Bench for conducting evaluations of actual engines, bench for conducting environmental evaluations of actual engines, bench for conducting evaluations of actual compressors

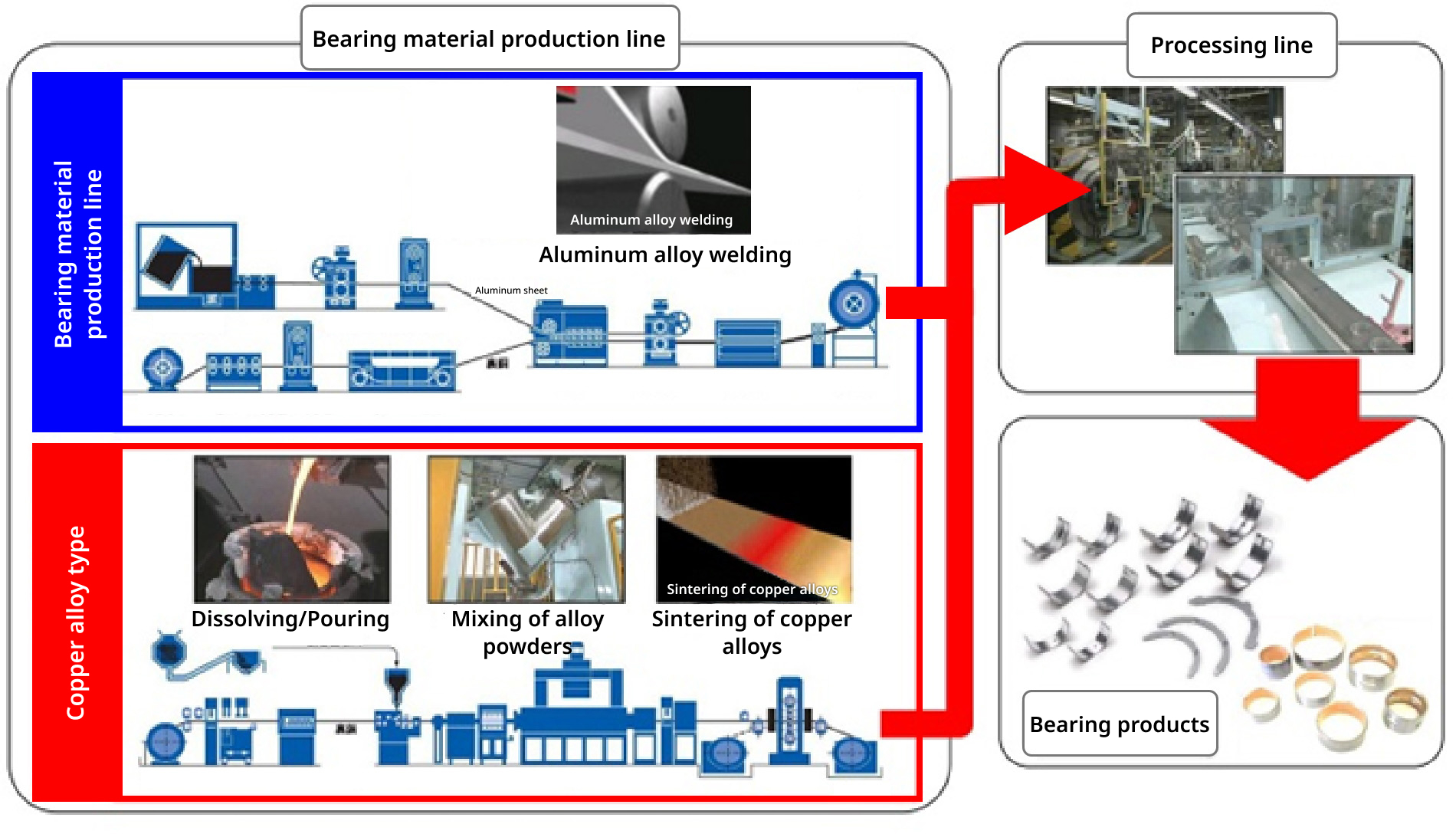

An integrated production system encompassing everything from materials to products

Harnessing an integrated production system encompassing everything from materials to products to realize efficient product development and high levels of quality and productivity

Quality assurance beginning with materials is important for producing exceptional products. For our bearing products, an integrated production system designed to enable constant quality control to be exercised in all processes from the production of materials to the completion of products has been implemented. The concept of integrated production that combines a variety of production technologies, such as those related to casting, precision machining, assembly, fabrication, and transportation, and high-level quality control technology is also applied to products other than bearings and allows us to quickly accommodate the launching of new products.