Development aims

Clarifying the mechanism by which cavitation erosion occurs and setting design criteria can help improve the quality of bearing/peripheral design and the speed by which such design is developed from the initial stages of engine design.

Development concept

What is cavitation erosion?

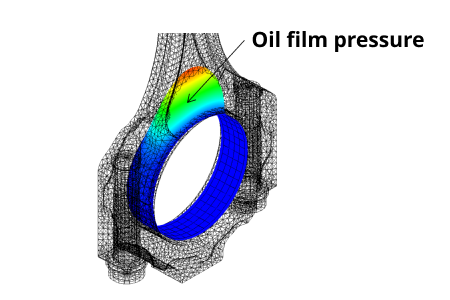

It is a phenomenon by which, as a result of air bubbles in the oil film collapsing at high speed due to rapid changes in pressure in the oil film, the impact pressure at the time these air bubbles collapse acts on the bearing and causes surface damage ⇒ fatigue fracture.

Mechanism by which cavitation erosion occurs

It is a phenomenon by which, as a result of air bubbles in the oil film collapsing at high speed due to rapid changes in pressure in the oil film, the impact pressure at the time these air bubbles collapse acts on the bearing and causes surface damage => fatigue fracture.

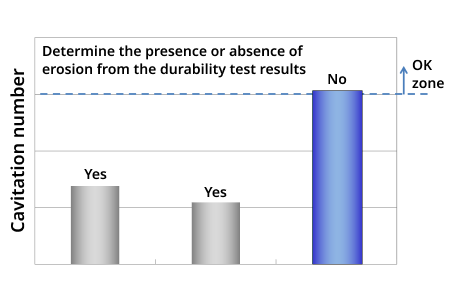

Cavitation number

The bigger the cavitation number, the more effective the suppression of erosion

Confirming effectiveness

The cavitation number is calculated using the average oil film pressure value as the main flow pressure value based on the results of the EHL analysis of the connecting-rod bearing. This is applied to Model A and the criteria are set based on the results of the evaluation of durability.

→Measures can potentially be taken by narrowing the width and optimizing in terms of oil relief and clearance.