Development aims

End plates for FCs

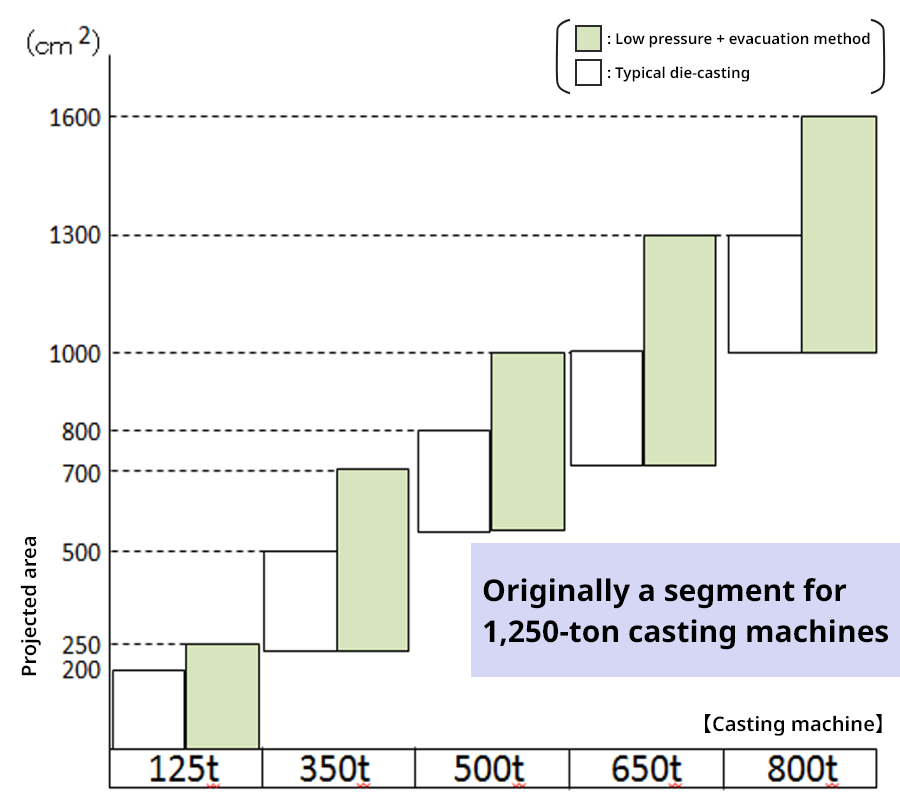

- Downsizing casting machines by lowering the casting pressure from 1,250 t to 800 t

- Lower weight and costs through the adoption of an optimal rib design

Castable projected area

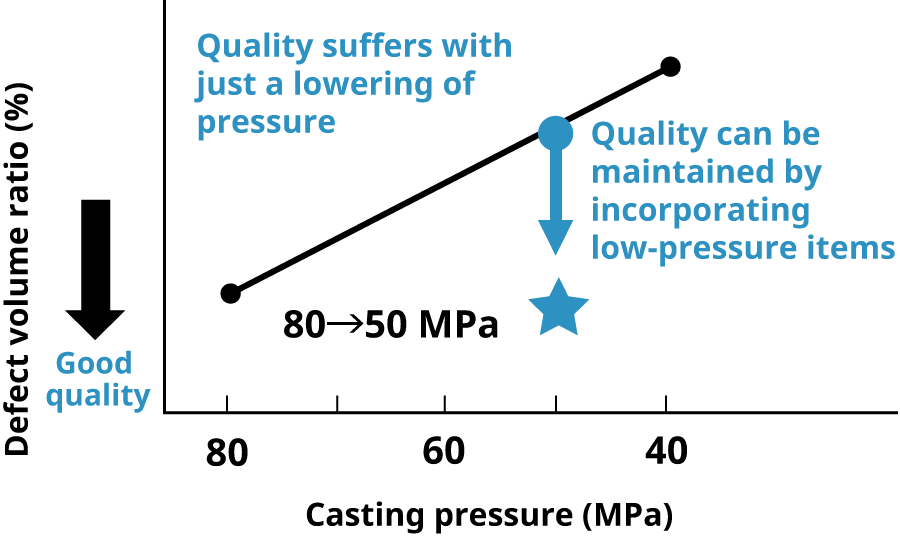

Development concept

Downsizing of machines

Item to reduce casting pressure

- Die temperature control

- Practical application of die surface treatment

- CAE-based predictions of casting defects (product form and casting plan)

- Injection speed increase

- Increased sleeve filling rate

Low pressure technology image

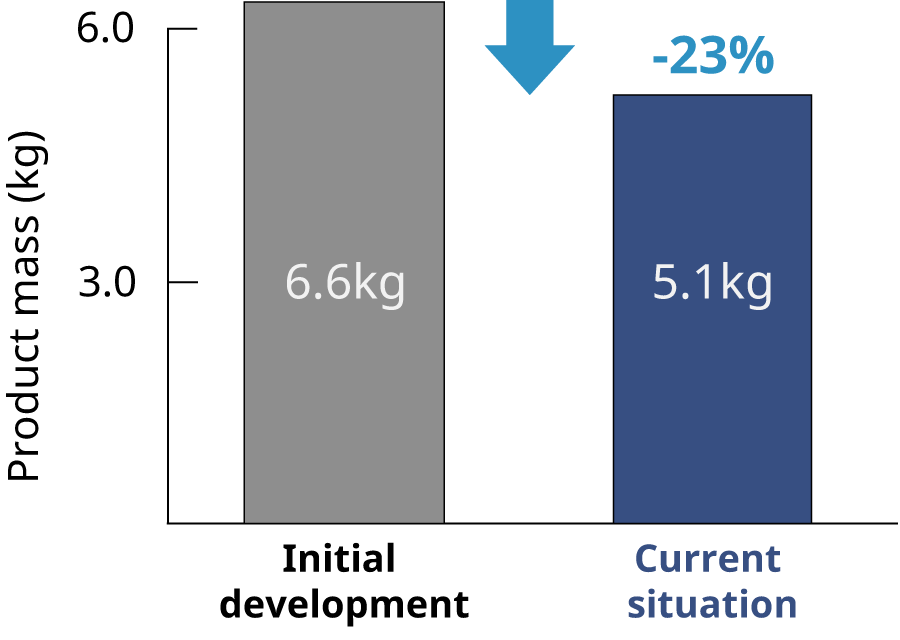

Lightweight design by utilizing CAE

- Implemented optimal rib arrangement and lightweight design by combining strength and die-casting manufacturing requirements

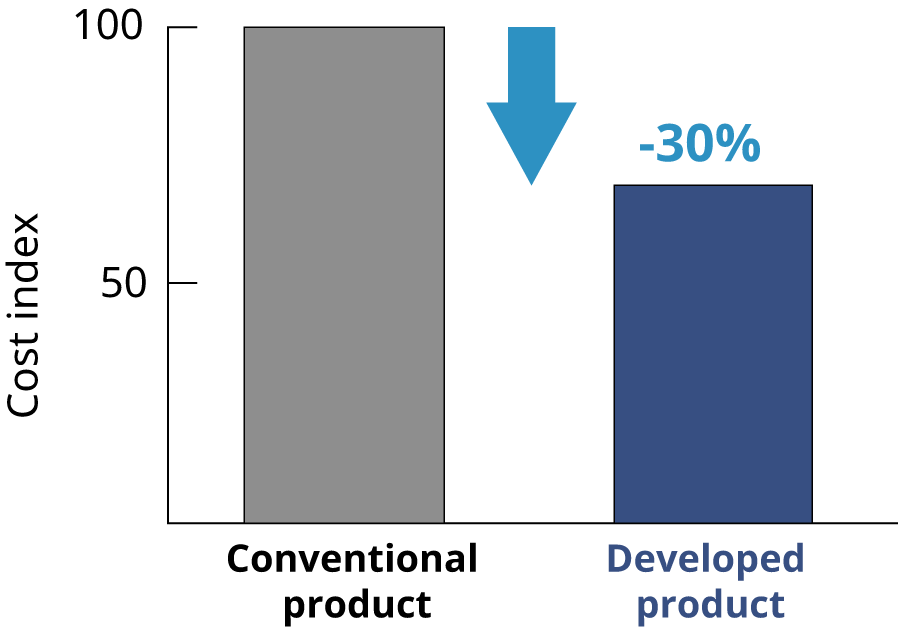

Confirming effectiveness

Downsizing of machines

Casting cost reduced by about 30% compared to conventional products

Lightweight design by utilizing CAE

Maintains required strength and reduces mass by 23%

Application example

- End plates for FCs

- Valve body, etc.